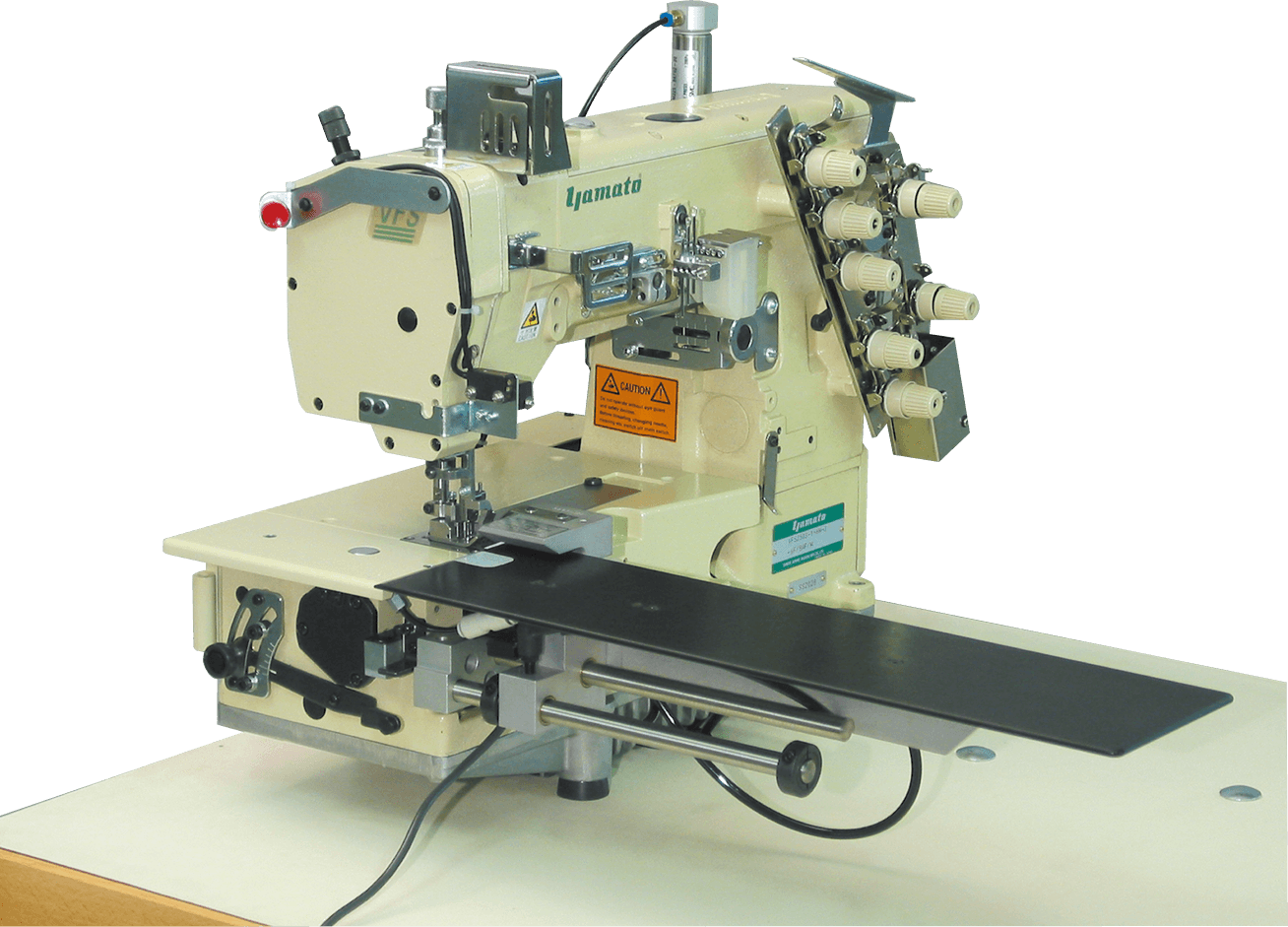

High Production & Deskilling Sleeve Hemming WorkstationBAF-S-VFS2511-8

Even a beginner can handle the sleeve hemming operation with uniform and high quality finish

- The top feeder feeds the work straightforward, and air guiding hemming folder sets operator free from handling. Thanks to those features, even a beginner can handle the operation with a minimum training period.

- 600 to 700 dz. pcs per 8 hours higher production ratio can be achieved. BAF-S minimizes fabric losses to save material costs which accounts for the majority of the material cost, because it employs "NO TRIM" method which does not trim fabric edges.

- Active Thread Control supports ideal seam over wide range from soft and elastic seams for microfibers to tight seams for outer wears.

Even a beginner can handle the sleeve hemming operation with uniform and high quality finish

The top feeder feeds the work straightforward, and air guiding hemming folder sets operator free from handling. Thanks to those features, even a beginner can handle the operation with a minimum training period.

High Productivity & Minimized Material Costs

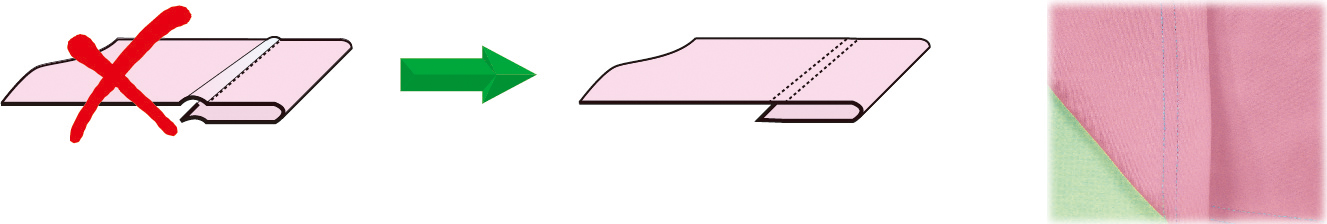

600 to 700 dz. pcs per 8 hours higher production ratio can be achieved. BAF-S minimizes fabric losses to save material costs which accounts for the majority of the material cost, because it employs "NO TRIM" method which does not trim fabric edges.

Yamato's signature Active Thread Control Technology

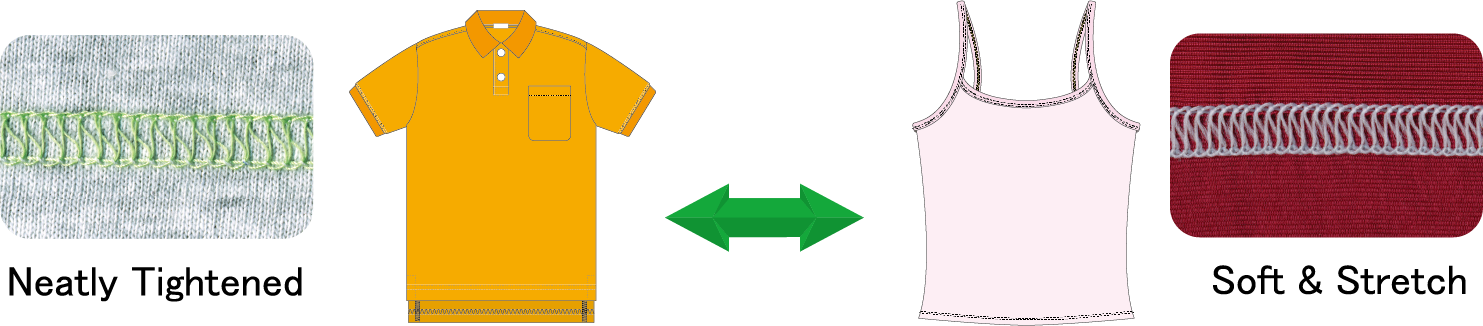

Active Thread Control supports ideal seam over wide range from soft and elastic seams for microfibers to tight seams for outer wears.

Even a beginner can handle the sleeve hemming operation with uniform and high quality finish

The top feeder feeds the work straightforward, and air guiding hemming folder sets operator free from handling. Thanks to those features, even a begginer can handle the operation with a minimum training period.

High Productivity & Minimized Material Costs

600 to 700 dz. pcs per 8 hours higher production ratio can be achieved.

Besides, BAF-S minimizes fabric losses to save material costs which accounts for the majority of the material cost, because it employs "NO TRIM" method which does not trim fabric edges.

Minimize Downtime

Whole system is controlled by a servo motor for easy maintenance.

Furthermore, BAF-S can be easily converted to a different use because the hem folder can easily be removed.

Suitable for microfibers. Active Thread Control supports ideal seam over a wide range from soft and elastic seams for microfibers to tight seams for outer wears

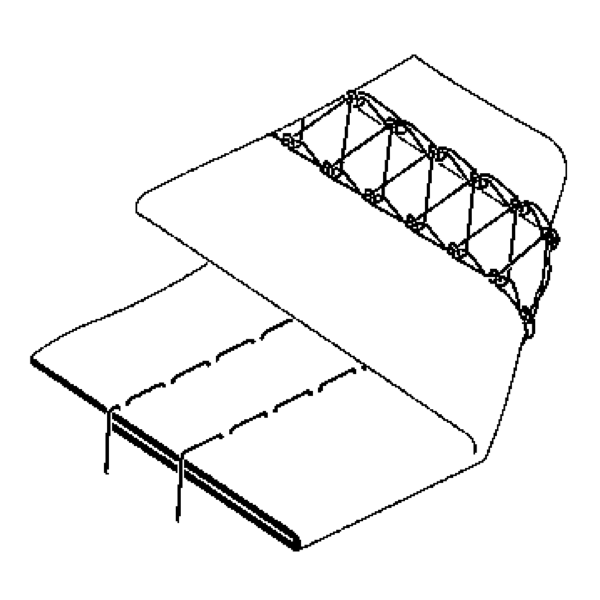

Epoch-making soft and elastic seams suitable for microfibers

If you are looking at further flexibility for the recent frequent and big change in sewing condition, Yamato's signature "Active Thread Control" is the right technology.

Active Thread Control performs epoch-making soft and elastic seams suitable for garments with lightweight, soft and stretchable microfibers, such as athletic wears or ladies' intimates.

Unlike the conventional way of thread control, which mainly use tension (resistance) on each thread, Yamato "Active Thread Control" takes in and draws back thread when it is required, and well-balanced seams with minimum necessary tension(resistance) for thread regulation.

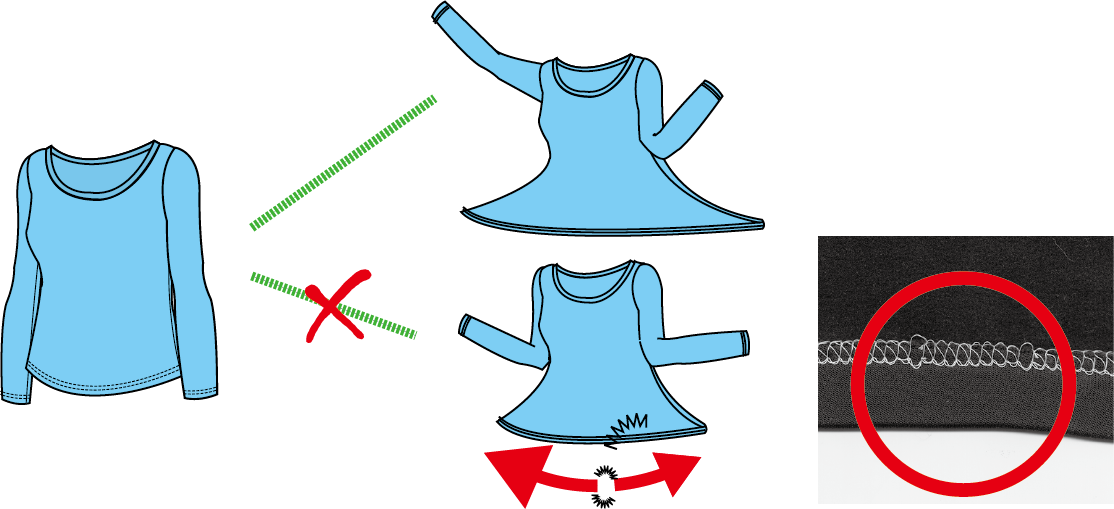

The soft and elastic seams made with Active Thread Control offer the tunnel free finish preventing seam breakage.

Tunnel Free Finish, Comfortable to Wear

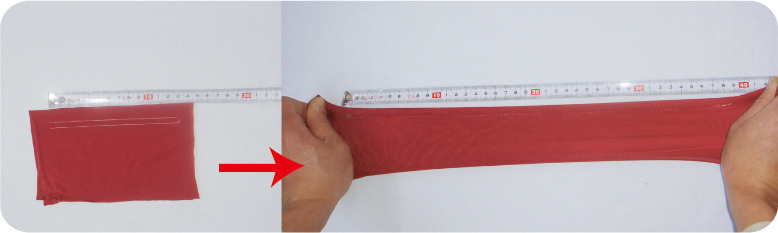

200% plus stretch!

High streatch seaming prevents seam breakage.

Ideal seam over wide range from soft and elastic seams for microfibers to tight seams for outer wears

Making ideal seams over wide range, Active Thread Control supports wide variety seams from soft and elastic seams to tight seams. Yamato Active Thread Control makes ideal thread balance control to form any desiered seam, with less stress given to each thread.

Adjustment from soft to tight seam can be done simply and visibly, addressing frequent changes of sewing conditions.

Wide variety of seams can be performed with Active Thread Control, by the simple and "visible" adjustment, not by the "fuzzy" adjustment tension devices.

Adjustment from soft to tight seam can be done simply and visibly to minimize required skills and downtime spent for addressing frequent changes of sewing conditions.

日本語

日本語  中文

中文