Electronically Controlled Chainstitch Straight Buttonhole Machine for Decorative Non-functional Buttonholes on Jacket SleevesAMF Reece S4000-ISBH/YIX-II

Electronically Controlled Chainstitch Straight Buttonhole Machine for Decorative Non-functional Buttonholes on Jacket Sleeves

- The S4000-ISBH is an electronically controlledchainstitchstraightbuttonhole machine designed for sewing decorative non-functional buttonholes on jacket sleeves.

Hand Stitching Like Appearance

S4000ISBH provides hand stitching like appearance for decorative non-functional buttonholes on men's and ladies' jacket sleeves.

Threads Can Be Changed During The Sewing Cycle

Indexer can be set to feed from left to right, right to left or to alternate between both. This feature is used when the work comes to the operator in pairs.

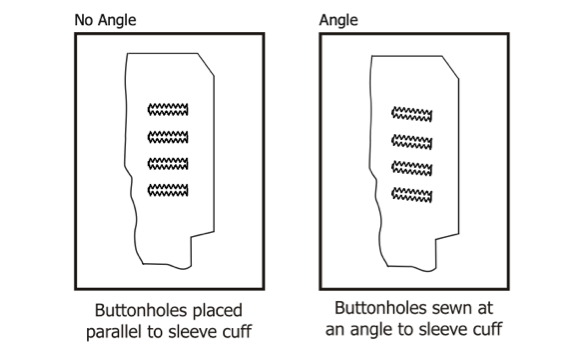

Upto 0 - 20 Degree Angle

Compatible with most applications of decorative non-functional buttonholes on jacket sleeves.

Applications

The S-4000 ISBH machine is used when sewing imitation non-functional buttonholes on sleeve cuffs of men's and ladies' jackets, suits and sport coats etc.

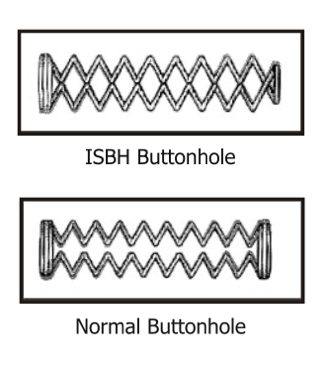

Hand Stitching Like Appearance

The Appearance of Imitation Sleeve Buttonhole is different to a normal buttonhole which is squared at both ends. The ISBH non-cut buttonhole has one squared end and the other „show” end has less stitches which gives a rounded effect. This is achieved by the use of a special cam. On the finished garment the button is sewn over the squared end.

Electronic Stop and Start Motion

Electronic Stop and Start Motion extends machine life and improves machine reliability by eliminating the stop motion and clutch mechanisms.

High Sewing Speed combined with low noise level is adjus- table from 1,500 spm to 3,800 spm.

Built-In Motor

DC Drive Motor fully enclosed within the head casting eliminates the need for an under the table mounted cluth motor, pulley, belt and brake. This reduces required mainte- nance and eliminates oil and dust around the working area.

Pneumatic Thread Trimming and Clamping

Pneumatic System is used for the thread trimming and clamping that reacts to different material thicknesses and types of fabric. Together with the Single Pedal Electronic Start it increases production and reduces operator ́s fatique.

Semi-Automatic Lubrication System and Oil Monitor

Semi-Automatic Lubrication System and Oil Monitor provide additional safeguards that increase machine life and dependability.

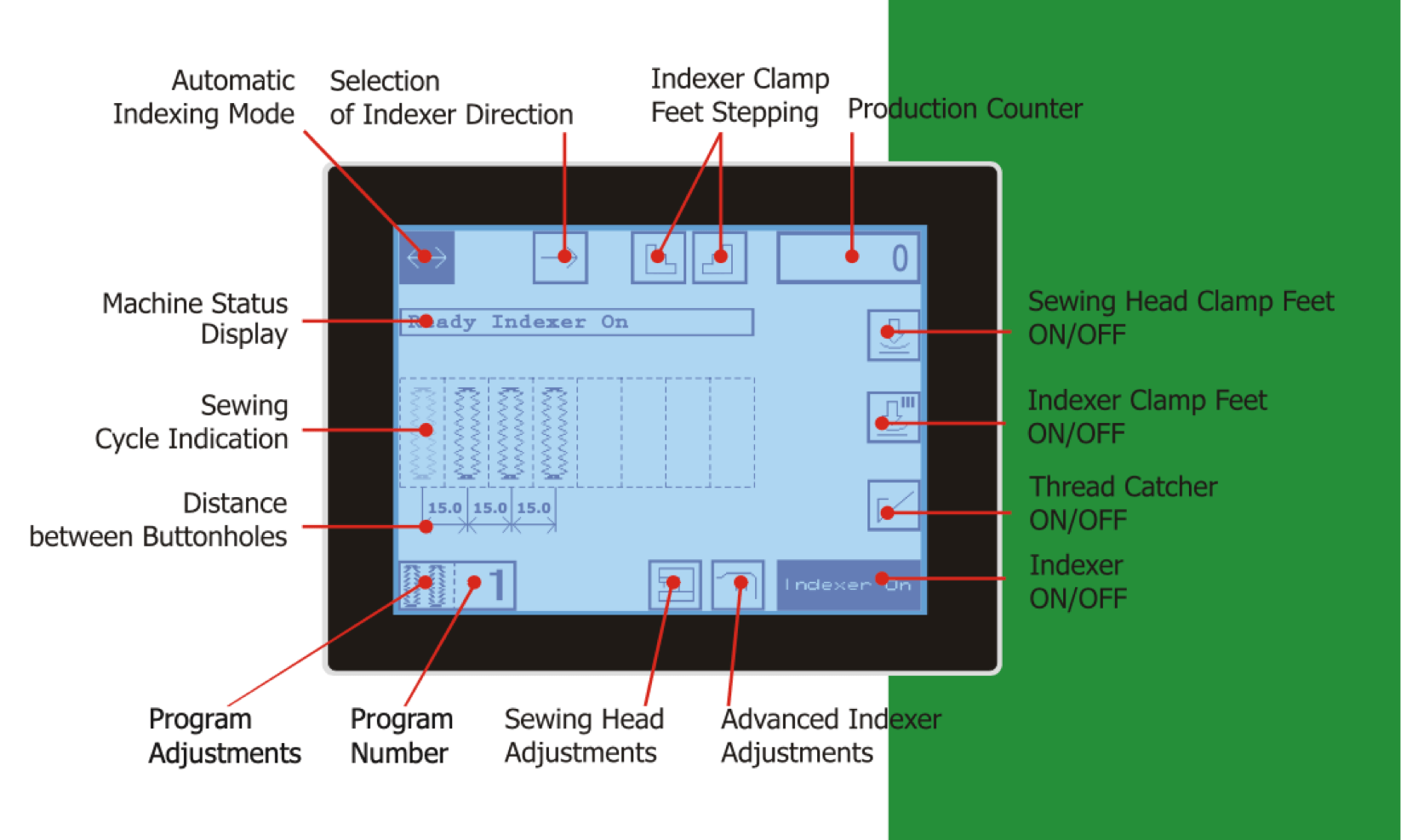

Touch Panel Screen

S-4000 ISBH with Indexer is programmable to sew imitation buttonholes at specific distances between each buttonhole. The number of buttonholes and the distance required bet- ween them are selected by the operator on the control panel.

Overlapping Operation

When using the S-4000 ISBH with Indexer, the operator simply places the sleeve cuff into the correct sewing position for the first buttonhole and during the sewing cycle prepares the next piece for sewing.

Threads Can Be Changed During The Sewing Cycle

Indexer can be set to feed from left to right, right to left or to alternate between both. This feature is used when the work comes to the operator in pairs.

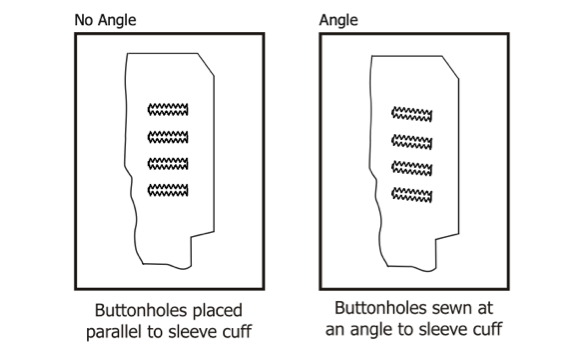

Upto 0 - 20 Degree

The machine clamps can be set to sew imitation buttonholes at an angle of 0 to 20 degrees from a sleeve cuff.

This feature is usually required when sewing buttonholes on ladies ́ jackets while on menswear the buttonholes are normally sewn parallel to the cuff.

日本語

日本語  中文

中文