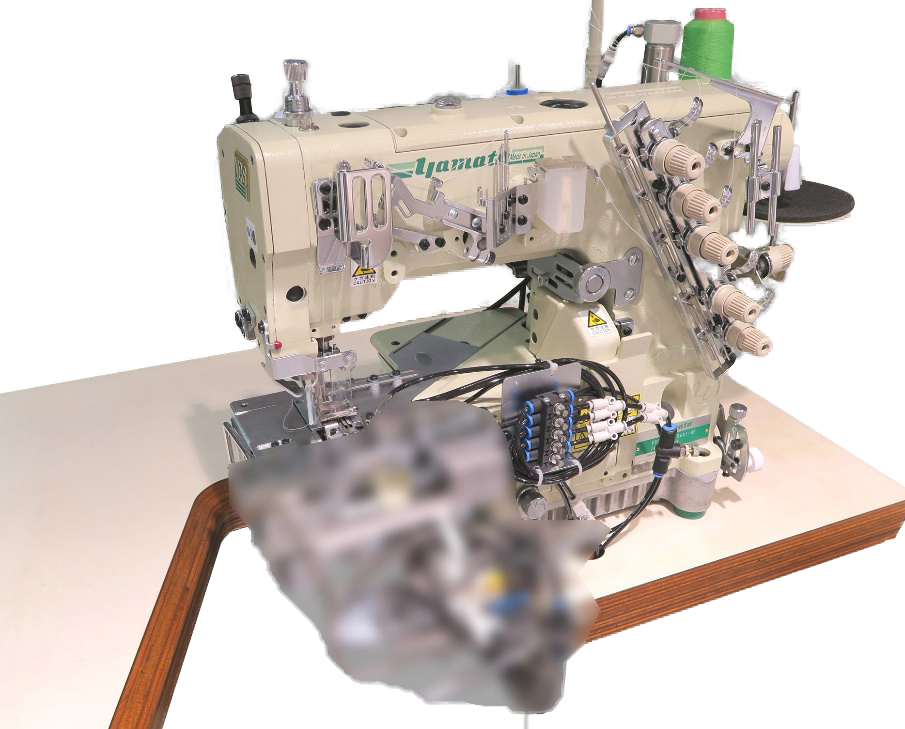

Semi-Automatic Easy Bottom Hemming WorkstationEZH-B

Critical Operation Can be "EZ" Now, with Yamato's Easy Hemming Workstation

- Circular hemming, one of the most critical operations on knitwear assembly has been much deskilled now

- Outstanding finishing quality can be achieved

- Contribute to quicker launch of new manufacturing plants

Circular hemming, one of the most critical operations on knitwear assembly has been much deskilled now

Offers further uniform quality with less sewing skill, allowing you high productivity and uniform finish. Also, learning curve of new operators can be improved.

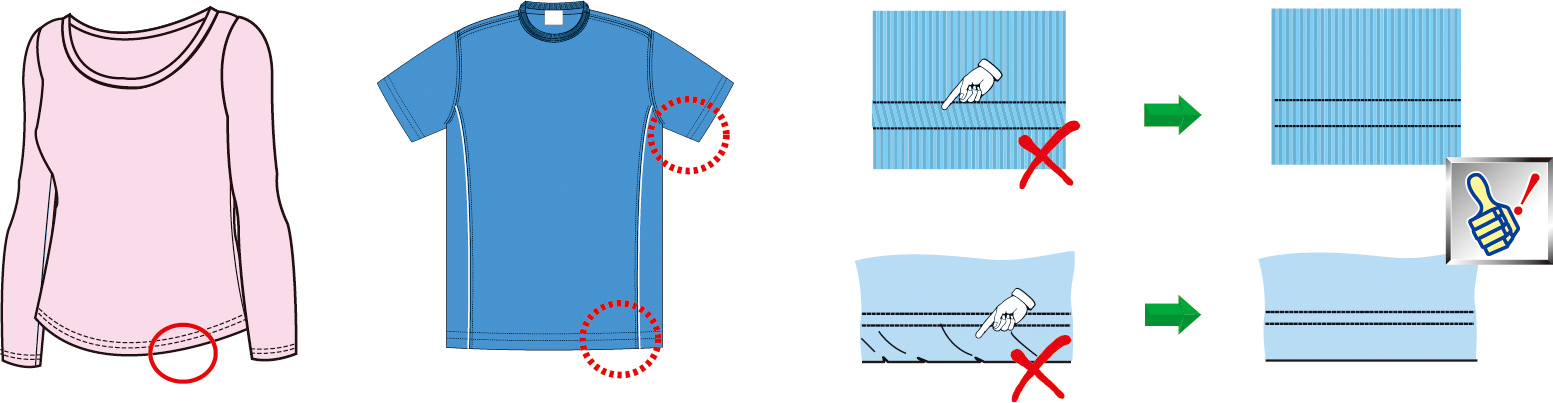

Outstanding Finishing Quality!

Iron-free perfect finish can be obtained, without roping, twisting or puckering.

Easy to Adapt to Different Sewing Conditions

Simplified electronics of EZH-B makes it easy to adapt to frequent changes of styles, hemming width or fabrics as easy as daily sewing machine maintenance.

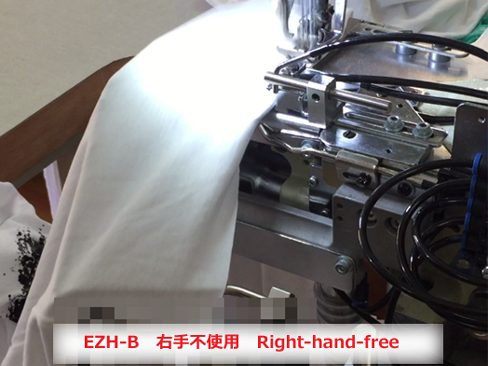

Circular hemming, one of the most critical operations on knitwear assembly has been much deskilled now

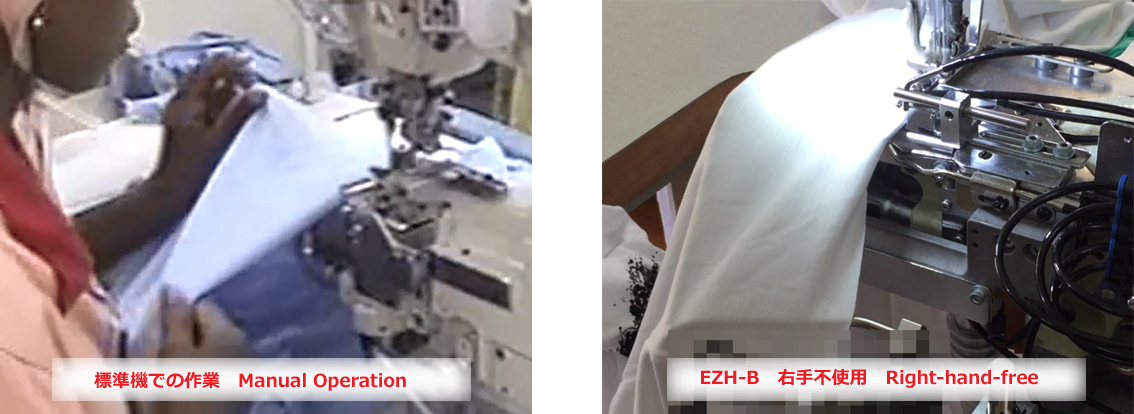

Appending the expert's right hand to the outstanding feeding performance of Yamato VGS3721.

EZH-B plays the role of the right hand of the expert operator. EZH-B makes the hem, maintain the hem and control the edge of fabrics.

Required jobs to operators are reduced to loading the work, overlapping and unloading only. The rest is done by this workstation.

Therefore, EZH-B offers further uniform quality with less sewing skill, allowing you high productivity and uniform finish while minimizing the operators' fatigue which causes uneven quality. Also, learning curve of new operators can be improved.

Outstanding Finishing Quality!

In contrast with the standalone sewing machines or conventional automatic machines, EZH-B reliably feeds fabrics in a relaxed condition, thanks to the top feeder and Yamato's unique Active Thread Control technology. Therefore, iron-free perfect finish can be obtained, without roping, twisting or puckering.

Also, the ideal seaming quality with an appropriate thread tightness without tunneling can be realized thanks to Yamato's unique Active Thread Control technology.

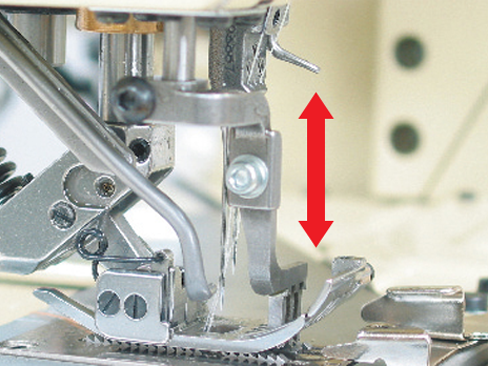

Easy to Adapt to Different Sewing Conditions

Simplified electronics of EZH-B makes it easy to adapt to frequent changes of styles, hemming width or fabrics as easy as daily sewing machine maintenance.

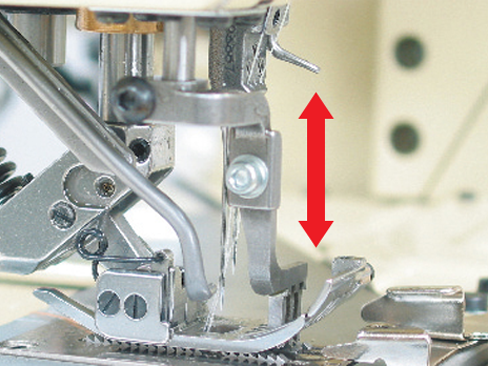

Thanks to the flat fit top feed dog equipped on VGS3721, configuration of the top feed dog for different material thickness can easily be made regardless to the pressor foot positioning.

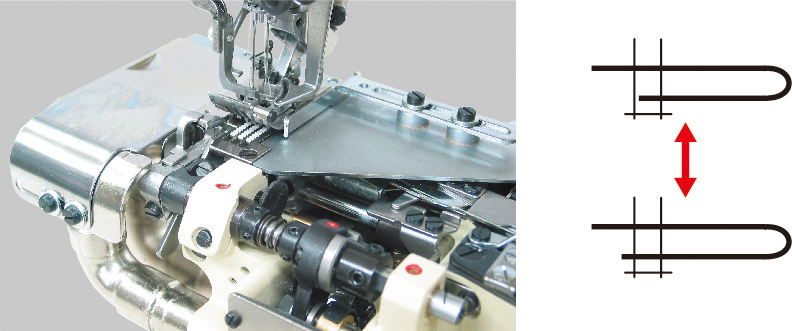

In addition, distance between the fabric edge to the seam can easily be fine-tuned mainitaining knives' positioning thanks to the unique micro-adjuster.

Avoid the seam unraveling. Further value with Yamato's unique Q-finish

Yamato's unique Q-finish avoids unraveling by forming an anchor by needle thread at the end in order to avoid seam unravelling from the end. "Q-finish" enables elimination of tacking operation done by single needle lock stitch and bar-tacker.

Benefits of eliminating tacking process - Increase productivity, better looking and more comfortable to wear

日本語

日本語  中文

中文