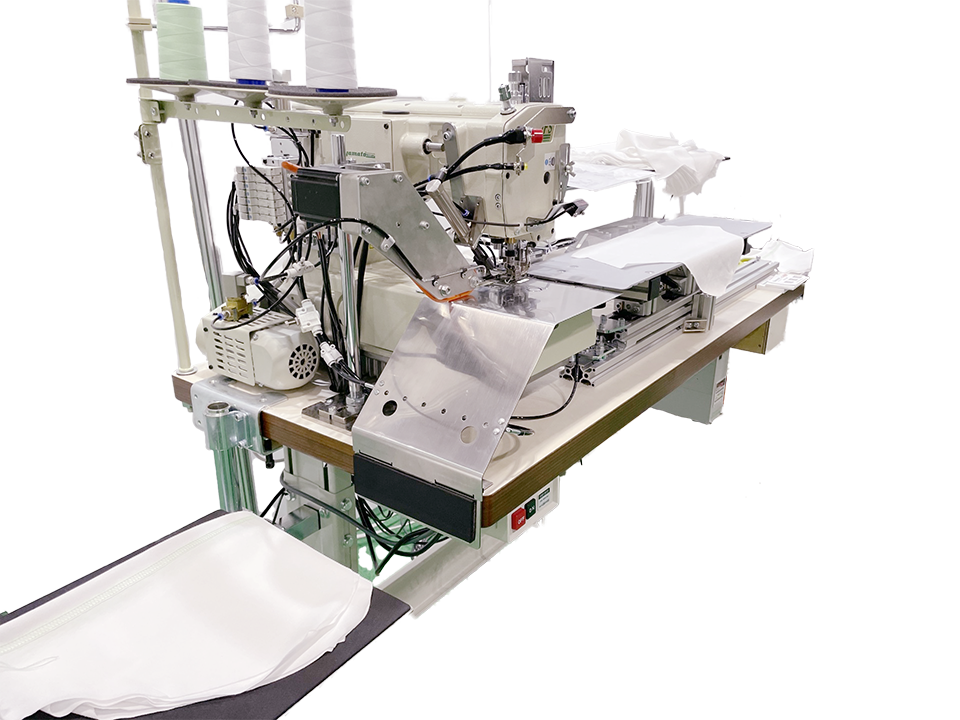

Semi-Automatic Easy Open Sleeve Hemming WorkstationEZH-S1000

Automation of all processes for open sleeve hemming

Enables high speed and stable production without skilled workers

- Automate all processes in the open sleeve hemming, including hem formation, sewing, thread trimming, and stacking

- Even novice operators can quickly produce equal quality products at high speed. Contributes to maximizing profits in a short period of time.

Automate all processes in open sleeve hemming

Yamato EZH-S1000 automates all processes in open sleeve hemming, including hem formation, sewing, thread trimming, and stacking.

The only part of the operator's intervention is the setting of the fabric, which requires no skill, allowing even novice operators to quickly achieve high-speed production of equal quality products and maximize profits in a short period of time.

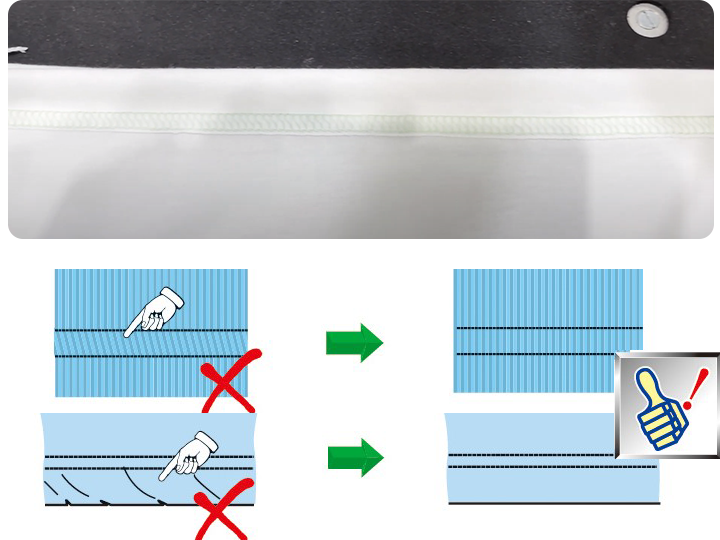

Stable production of high-quality products

Flat finish without roping, twisting or puckering

Thanks to the differential top feeder, fabrics are feeded in a relaxed condition,

Therefore, iron-free flat finish can be obtained, without roping, twisting or puckering.

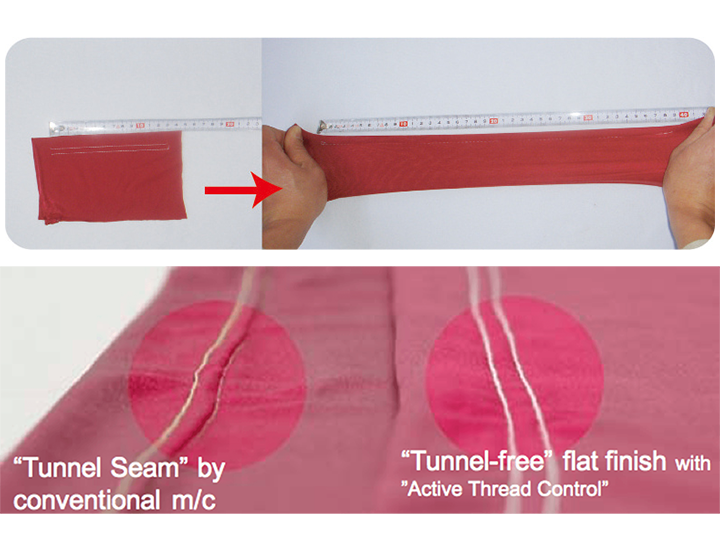

Soft seams suitable for stretch materials

In combination with Yamato's unique active thread control mechanism, soft and stretchy seams are achieved for stretchy materials.Stretchable seams prevent the flexible, stretchy materials from tunnel seam, and also prevent damage to the seams due to pulling when worn.

日本語

日本語  中文

中文